Why Prototyping Is Critical to PCB Success (And How UK Manufacturers Speed It Up)

Prototyping is one of the most important stages in the PCB development journey, yet it is often underestimated. A well-executed prototype validates design intent, exposes hidden manufacturing issues and ensures the product performs reliably before entering full-scale production. Whether the application is medical, industrial, automotive or consumer electronics, early-stage prototyping protects your project from delays, redesigns and financial risk.

Across the UK, manufacturers are adopting new techniques, faster turnaround workflows and more collaborative engineering models to help customers develop prototypes quickly and accurately. With supply chains tightening worldwide, British businesses increasingly value the reassurance of a local partner who can provide technical insight, rapid response and dependable build quality.

In this article, we explore why prototyping has become a crucial stage in modern PCB design, what it prevents, and how UK assembly specialists now accelerate the development cycle without compromising reliability. If you’re responsible for designing, sourcing or delivering electronic products, understanding the value of prototyping will help you avoid costly pitfalls and strengthen long-term product success.

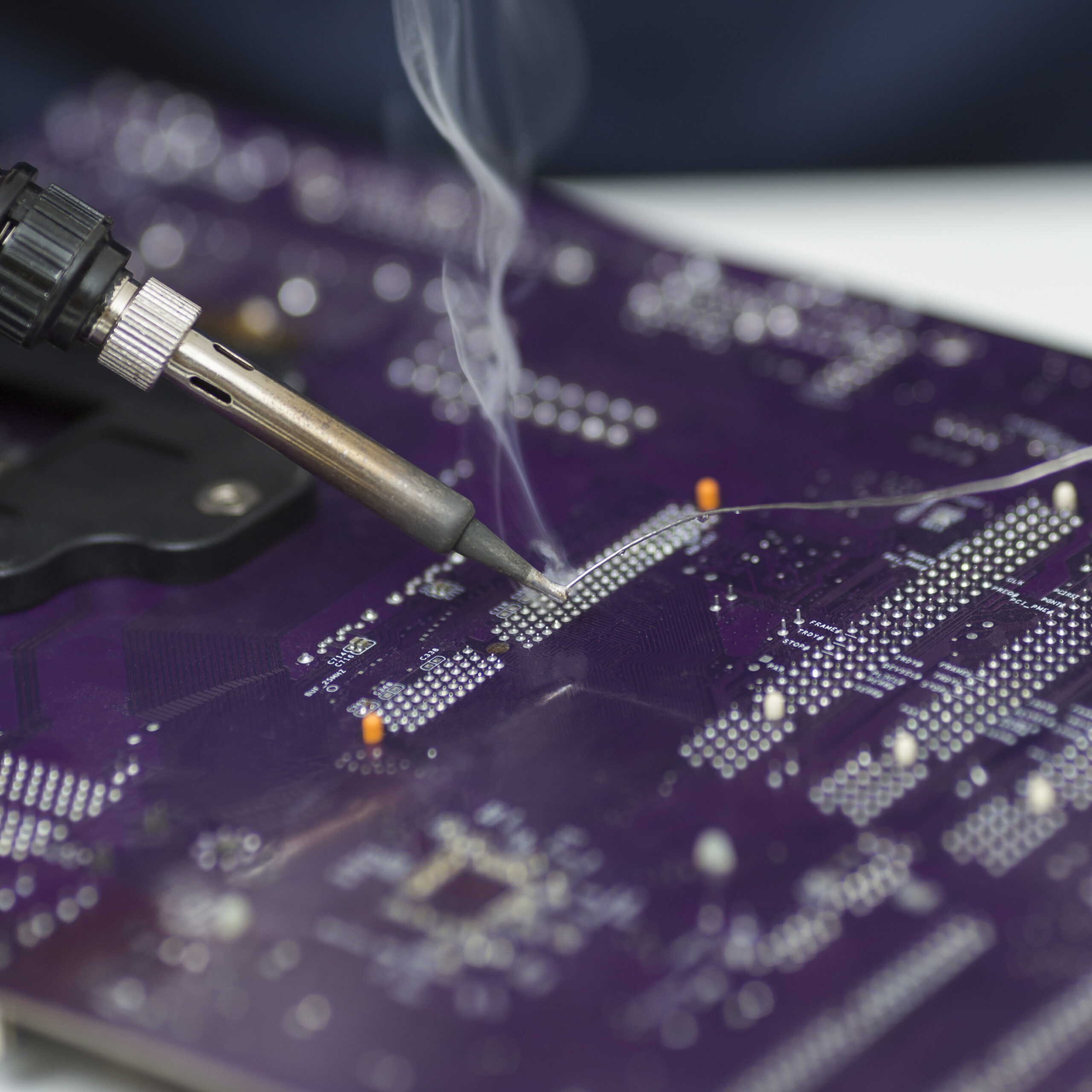

Rapid prototyping helps uncover issues that may not appear during design simulations or layout review. These may include thermal inconsistencies, manufacturability problems, component fit issues, solderability behaviour and real-world electrical performance. Modern UK manufacturers now integrate DFM reviews, design support and trial builds to help identify problems early while keeping turnaround times short.

By collaborating closely with design teams, prototyping partners help ensure that the final product is both practical to assemble and reliable in long-term operation.

What PCB Prototyping Actually Reveals

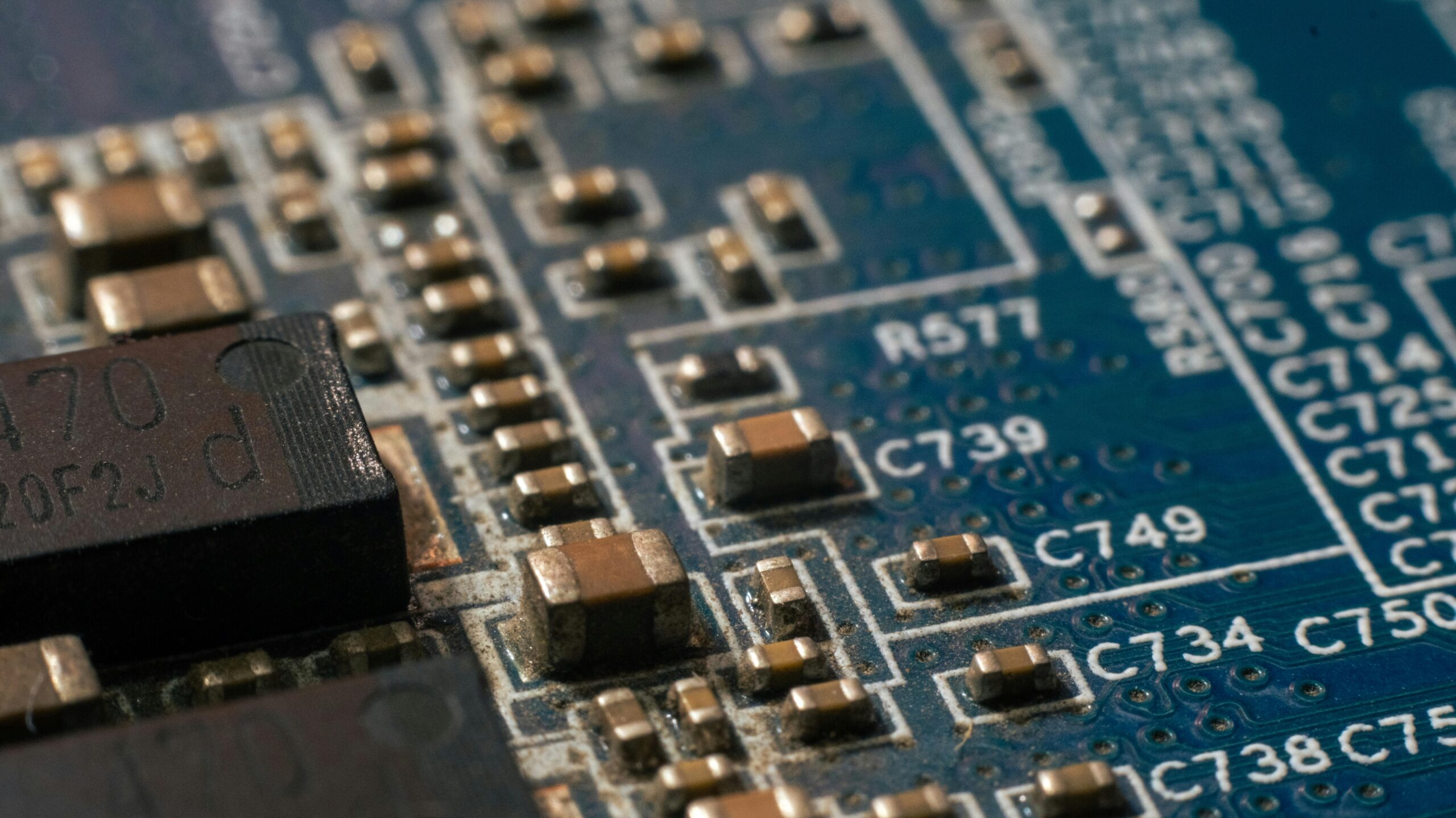

Even the most carefully designed PCB can behave differently when built in the real world. Prototyping exposes issues such as incorrect pad sizing, insufficient copper balancing, signal integrity variations, unanticipated EMI noise, thermal hotspots and component tolerances that deviate in practice.

Prototypes also reveal mechanical constraints—such as enclosure fit, connector reach, port alignment and cable routing—that CAD systems often struggle to simulate accurately. These checks are essential for avoiding late-stage redesigns, which can lead to costly delays, missed market windows or bulk scrappage.

Many UK manufacturers now incorporate X-ray inspection, AOI, functional test and even environmental simulation as part of their prototype evaluation, helping teams make fast, confident decisions before locking in design files.

Small-scale builds also allow manufacturers to refine solder processes, review reflow profiles, assess voiding levels and examine joint quality under microscopes or X-ray systems. These insights lead to higher reliability when the design progresses to production, particularly for BGAs, QFNs and high-density SMT packages.

By validating the real behaviour of the PCB early on, UK manufacturers help customers avoid the risks associated with untested designs entering full-volume manufacturing.

The Rise of Rapid Prototyping in the UK

British PCB assembly providers are increasingly offering fast-turn prototype services to support innovation cycles in industries such as defence, medical devices, industrial automation and consumer products. These services are designed to deliver functional boards in days rather than weeks, helping engineers verify design intent quickly and keep projects moving forward.

To achieve this, UK manufacturers have invested heavily in flexible SMT lines, rapid programming tools, quick-change feeders and adaptable reflow processes. This allows them to switch from one-off prototypes to small-batch runs with minimal downtime.

For customers, the result is shorter iteration cycles, faster validation and reduced time-to-market—especially valuable when developing competitive electronic solutions.

Rapid prototyping does not mean reduced quality. Instead, it prioritises efficiency and clarity—giving engineering teams fast, accurate feedback while still maintaining the standards required for long-term product reliability.

By partnering with a UK assembly house that balances speed with technical depth, companies can significantly reduce the risks and uncertainties associated with new product development.

How Prototyping Reduces Risk and Improves Final Product Quality

Thorough prototyping ensures that every part of the PCB performs as intended before entering full-scale production. This includes verifying solder joints, validating track integrity, ensuring correct component behaviour, and assessing thermal characteristics. Prototyping also highlights variability in component batches or fabrication tolerances that might otherwise remain hidden until it is too late.

These steps dramatically reduce the likelihood of field failures, warranty claims or expensive recalls—especially important for safety-critical sectors such as medical, automotive and aerospace.

For UK manufacturers, the ability to offer structured prototyping workflows with clear documentation, data reporting and engineering collaboration provides customers with a level of confidence that offshore suppliers often struggle to match.

Inspection also becomes more detailed during prototype analysis. Engineers use AOI, X-ray systems, oscilloscopes, power analysers and microscopes to build a clear understanding of how a design behaves under load. This level of insight is invaluable when optimising the next iteration of a board or when preparing for production ramp-up.

By addressing issues early, teams save time, money and engineering resources—protecting the long-term success of the final product.

What This Means for Engineers, Designers and UK OEMs

Prototyping is no longer just a preliminary step—it's a critical part of a product’s lifecycle. Engineers should now consider prototyping as an opportunity to refine layout, validate test strategies, improve manufacturability and eliminate risk long before committing to full-scale production.

UK OEMs and design houses increasingly rely on domestic prototyping partners due to the clarity, speed and communication they offer. With shorter supply chains, reduced shipping delays and easier collaboration, UK-based prototyping gives businesses greater control throughout the development cycle.

By selecting a manufacturing partner with strong prototyping capability, businesses can ensure faster iterations, better predictability and stronger overall performance in the final design.