Precision Surface Mount PCB Assembly (SMT)

Modern, accurate and reliable SMT manufacturing built for UK industries.

Phase One Electronics delivers precise SMT assembly using high-accuracy placement machines, controlled reflow profiles and skilled inspection. Trusted by UK businesses for over 35 years, we provide dependable prototype and production builds for demanding industries across Portsmouth, Hampshire and the UK.

What Is Surface Mount PCB Assembly (SMT)?

Surface Mount Technology (SMT) allows electronic components to be mounted directly onto the surface of a PCB. This enables modern, high-density circuitry with excellent reliability, repeatability and performance.

SMT assembly is essential for today’s electronics — supporting compact designs, complex microprocessors, fine-pitch ICs and ultra-small passives.

At Phase One Electronics, our SMT process combines automated placement machinery with controlled reflow soldering and careful human inspection.

This ensures every PCB is built with accuracy, consistency and long-term reliability.

Improved Electrical Performance

High-Density, High-Performance Electronics

Suitable for a Wide Range of Component Types

Reliable for Prototypes, Small Batches and Production

Why Choose Phase One Electronics for SMT Assembly?

For more than 35 years, Phase One Electronics has delivered high-quality SMT PCB assembly for industries that depend on consistent build quality and reliable performance. Our combination of automated precision, engineering oversight and careful inspection ensures dependable results across every batch.

Over 35 Years of SMT Experience

High-Accuracy Automated Placement

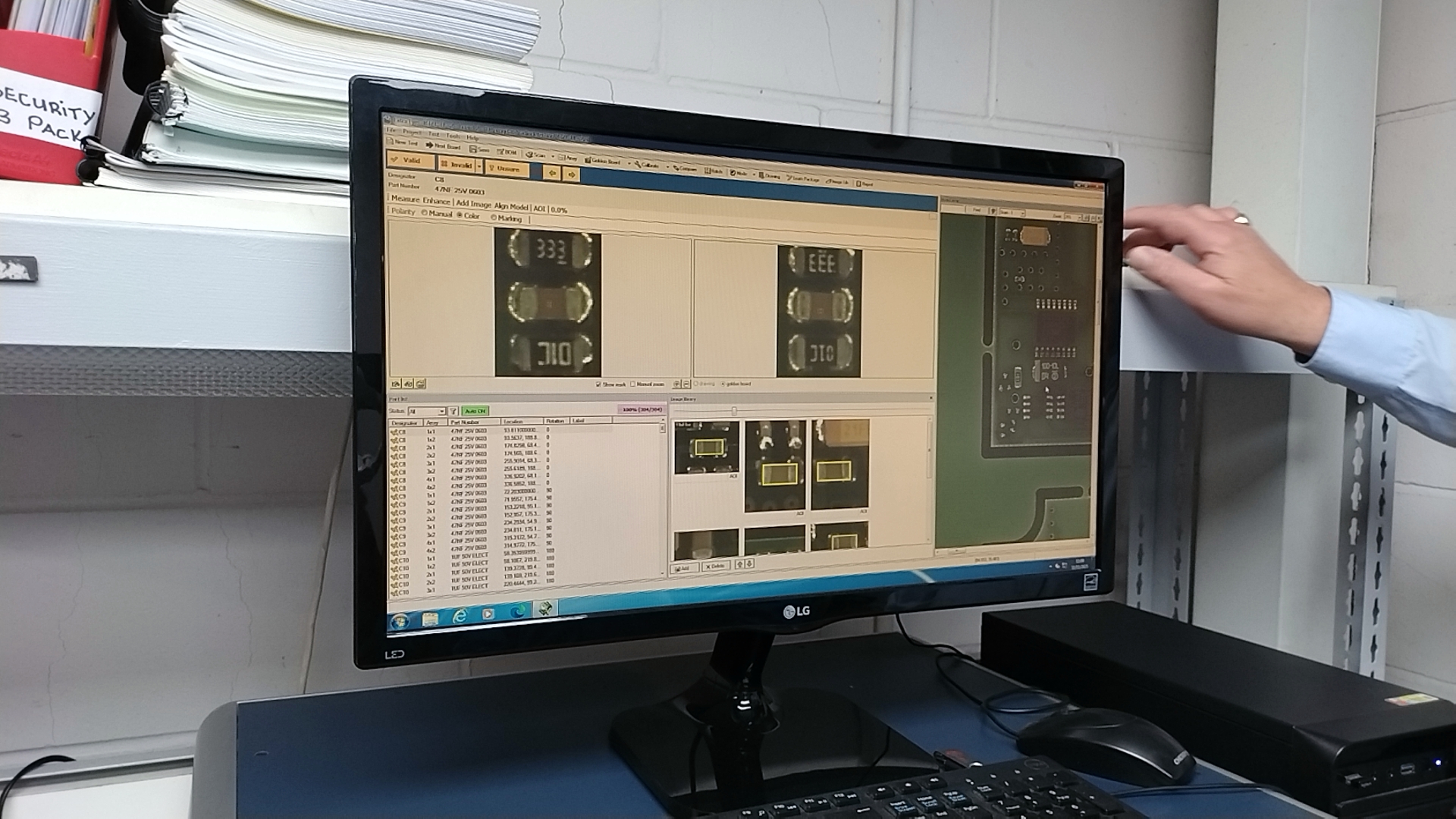

Skilled Human Oversight and Inspection

Flexible for Prototypes, Small Batches and Production

Engineering-Led Support and Honest Communication

All SMT Assembly Completed in the UK

Our Surface Mount Assembly Process

Our SMT process is designed to ensure accuracy, repeatability and long-term reliability. Every PCB follows a structured workflow that combines automated precision with careful engineering oversight and skilled manual inspection.

Data Preparation &

Engineering Review

Precision Solder

Paste Application

Automated Component

Placement

Controlled Reflow

Soldering

Manual Placement &

Hybrid Assemblies

Detailed Visual

Inspection

Testing & Functional Verification (Optional)

Industries We Support With SMT Assembly

Our SMT service supports a wide variety of industries that rely on performance stability, long-term reliability and consistent manufacturing quality. Many of our customers operate in demanding environments where precision and durability are essential.

From harsh environments to precision-driven applications, our SMT process is tailored to deliver long-term reliability, consistency and trusted performance.

Marine & Offshore

Medical & Laboratory Equipment

Industrial Automation & Control

Automotive & EV Systems

Consumer & Embedded Electronics

Telecommunications & Surveillance

Defence & Security

Free-Issue or Turnkey SMT Assembly

We offer both free-issue and turnkey SMT assembly options to suit your project requirements. Whether you prefer to supply components yourself or want us to manage procurement and traceability, our service is built to be flexible and efficient.

Free-Issue SMT Builds

Turnkey SMT Assembly

Full Build Documentation

Whether you choose free-issue or turnkey manufacturing, our focus remains the same: dependable SMT assembly with consistent quality and clear communication at every stage.

Request an SMT Assembly Quote

To provide an accurate quotation for your SMT project, please include your design files and any specific build requirements. Our team responds quickly, clearly and with complete transparency.