PCB Prototyping Services in Portsmouth

Fast, accurate and reliable prototype builds for UK engineers and product developers.

Every successful electronic product begins with a high-quality prototype. At Phase One Electronics, we provide rapid, dependable PCB prototyping for UK businesses developing new technologies. With over 35 years of manufacturing experience, we help engineers move from concept to functional hardware with speed, accuracy and confidence.

Why Choose Phase One Electronics for PCB Prototyping

We understand the pressures faced during product development — tight deadlines, evolving designs and a need for reliable results. Our PCB prototyping service is built around speed, accuracy and engineering support, helping UK innovators bring ideas to life.

With over 35 years of manufacturing experience and a strong reputation across Portsmouth and Hampshire, we provide dependable prototype builds backed by close communication, modern production methods and skilled workmanship.

Whether you need a single concept board or a short run of engineering samples, we ensure your prototypes are built correctly, inspected thoroughly and delivered on time.

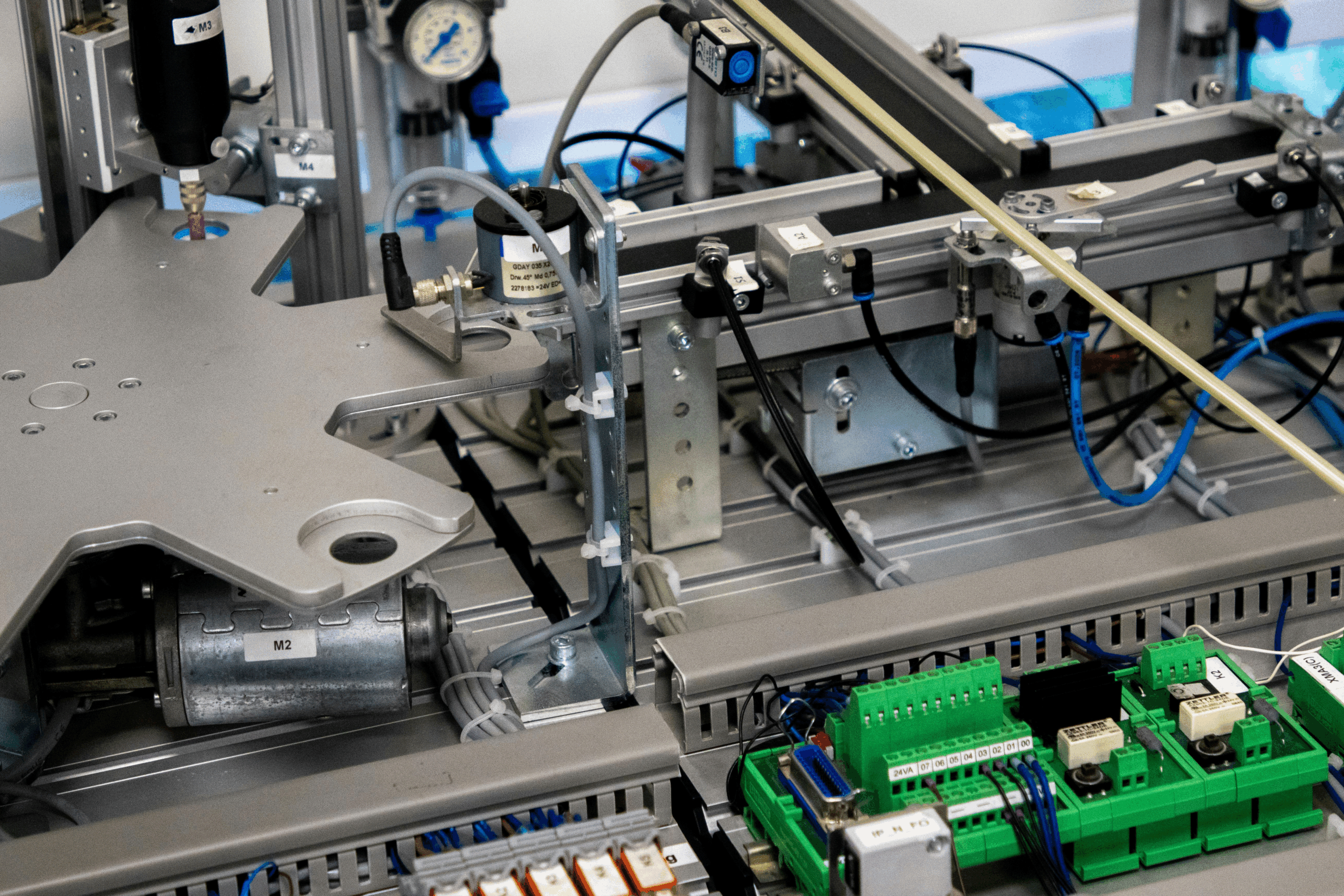

Our Prototyping Process: Built for Accuracy and Speed

Our prototype workflow has been developed over decades to provide engineers with dependable, repeatable results. Each stage is handled by skilled technicians and reviewed carefully to ensure your prototype behaves exactly as intended. Whether you are testing a concept, validating component choices or preparing for full production, our structured process protects your timeline and your design integrity.

Technical review & DFM feedback

Component sourcing & verification

Precision SMT assembly

Through-hole & odd-form assembly

Inspection & quality assurance

Firmware loading & testing

Industries We Support With PCB Prototyping

Our PCB prototyping service is trusted by engineers across a diverse range of UK industries. These sectors require accuracy, stability and reliable early-stage builds that help verify designs and prepare for full-scale production. With more than 35 years of manufacturing experience, we support prototype development for businesses where dependable hardware is essential to product success.

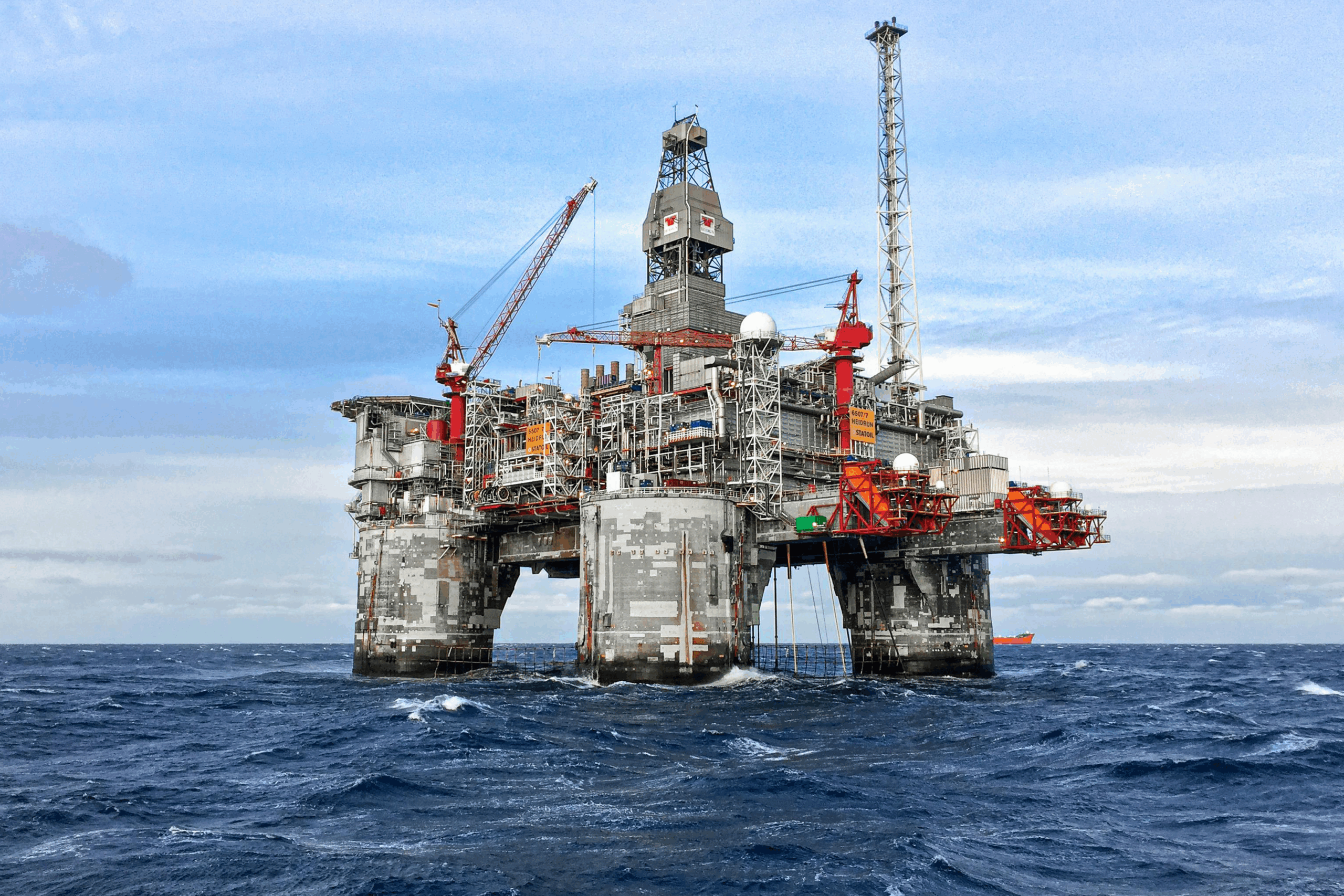

Marine &

Offshore

Defence &

Military

Automotive &

Electric Vehicles

Medical &

Healthcare Equipment

Telecommunications &

Surveillance

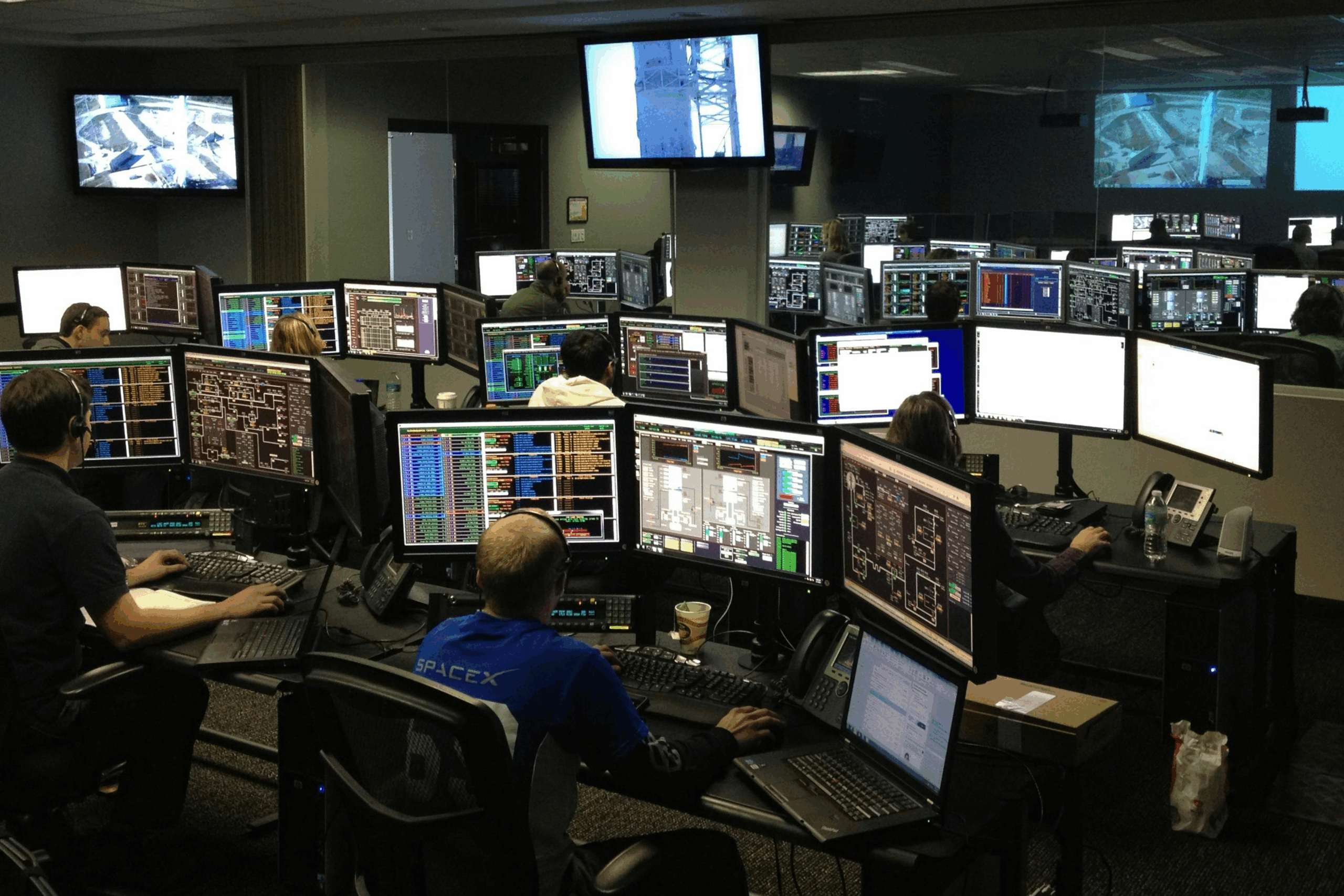

Industrial Automation &

Robotics

Rail, Transport &

Infrastructure

Audio & Music Industry

Prototype Quantities: From One-Off Builds to Pre-Production Runs

Our PCB prototyping service is intentionally flexible. Whether you need a single early-stage board or a small batch of pre-production units, we tailor our approach to match your development phase, budget and timescales.

One-Off Prototypes

Engineering Samples

Small Pilot Batches

Pre-Production Builds

Request a PCB Prototyping Quote

To provide a fast, accurate and dependable quotation for your prototype PCB build, please include the key project files and details listed below. This information enables us to assess manufacturability, component availability, assembly complexity and any special requirements—ensuring we deliver precise pricing and expert guidance from the start.