Cable Assemblies & Box Build Services in Portsmouth

Professional wiring looms, cable harnesses and full system integration for UK manufacturers.

We provide high-quality cable assemblies, wiring looms and complete box build solutions for businesses across the UK. With over 35 years of experience, our skilled technicians deliver clean, accurate and dependable wiring systems designed to support prototypes, production builds and fully integrated electronic products.

Why Choose Phase One Electronics for Cable Assemblies & Box Build?

We understand the importance of clean, accurate wiring and dependable system integration. With more than 35 years of manufacturing experience, our cable assemblies and box build services are designed to deliver consistent, high-quality results for industries where reliability cannot be compromised. Whether you need a simple loom or a fully integrated enclosure, our technicians work with precision and attention to detail at every stage.

35+ years of wiring and system integration experience

Complete UK-based production

Built to your exact specifications

Flexible batch sizes

Industry versatility:

Skilled wiring technicians

Our Cable Assemblies & Loom Manufacturing Process

Our cable assembly and wiring loom processes have been refined over decades to ensure accuracy, repeatability and reliability. Whether you require simple labelled leads, multi-branch wiring looms, or fully documented harnesses for regulated industries, our technicians follow structured procedures designed to deliver consistent results.

Documentation review

Precision cutting & stripping

Professional termination

Loom building & routing

Labelling & identification

Electrical testing

Our Box Build & System Integration Process

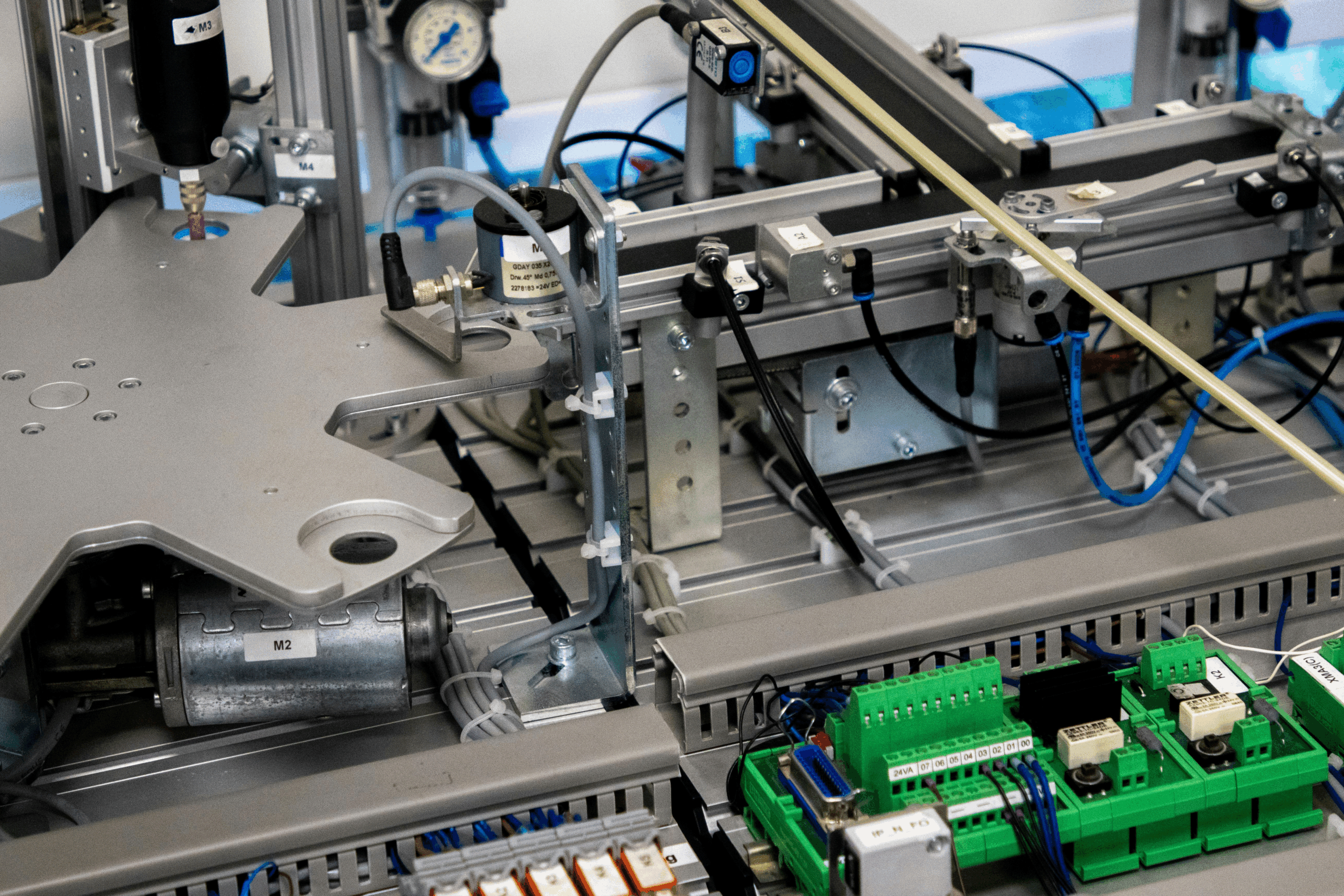

Our box build services bring together PCBs, wiring, power systems and mechanical hardware into complete, ready-to-use units. From simple control boxes to fully integrated electronic systems, we follow a structured process that ensures every enclosure is assembled cleanly, wired correctly and tested thoroughly before it leaves our facility.

Mechanical assembly & enclosure preparation

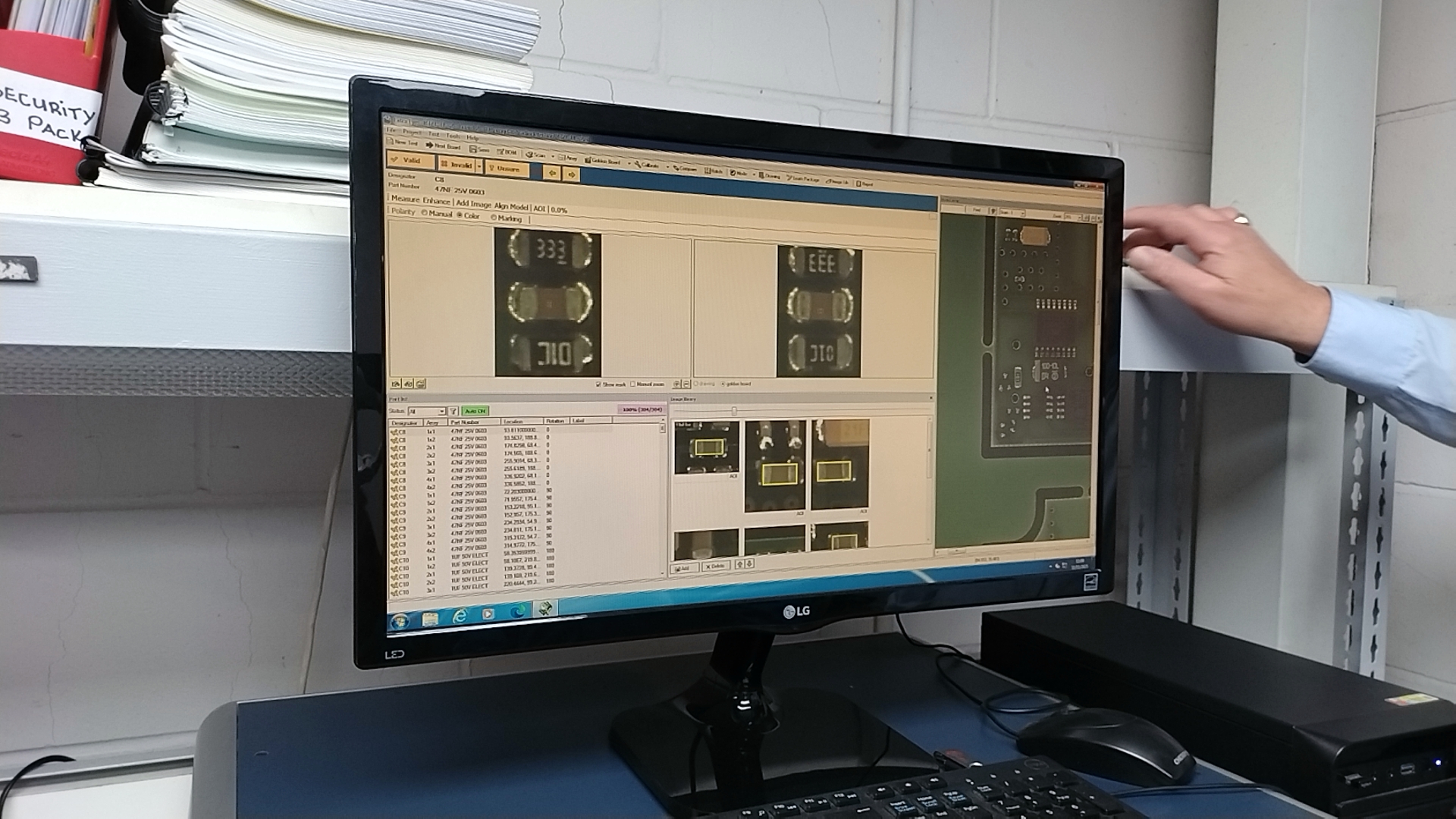

PCB integration

Internal system wiring

Power system installation

Final assembly and fit checking

Functional testing & verification

Industries We Support with Cable Assemblies & Box Build

Our cable assemblies and system builds are trusted by businesses across a wide range of industries.

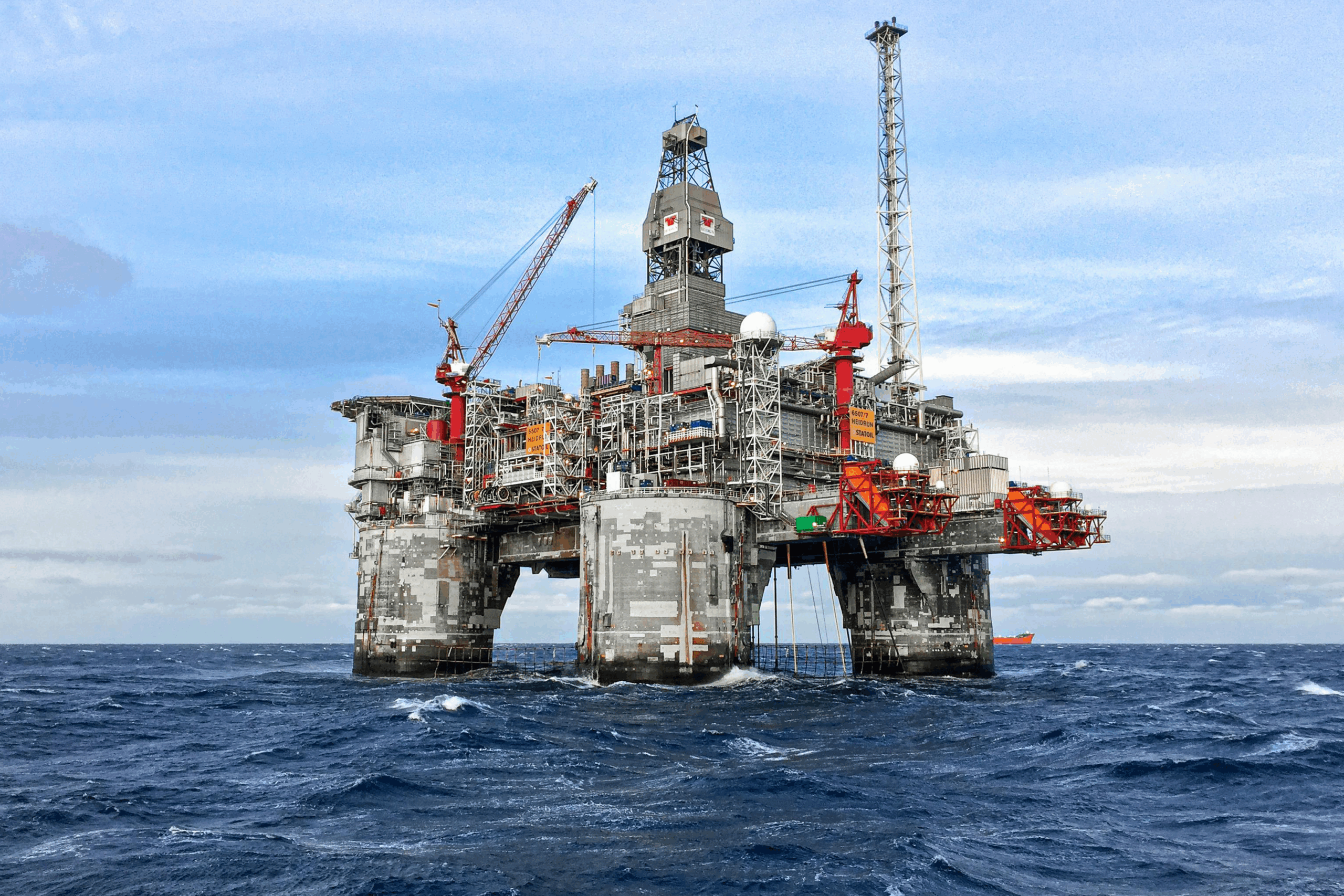

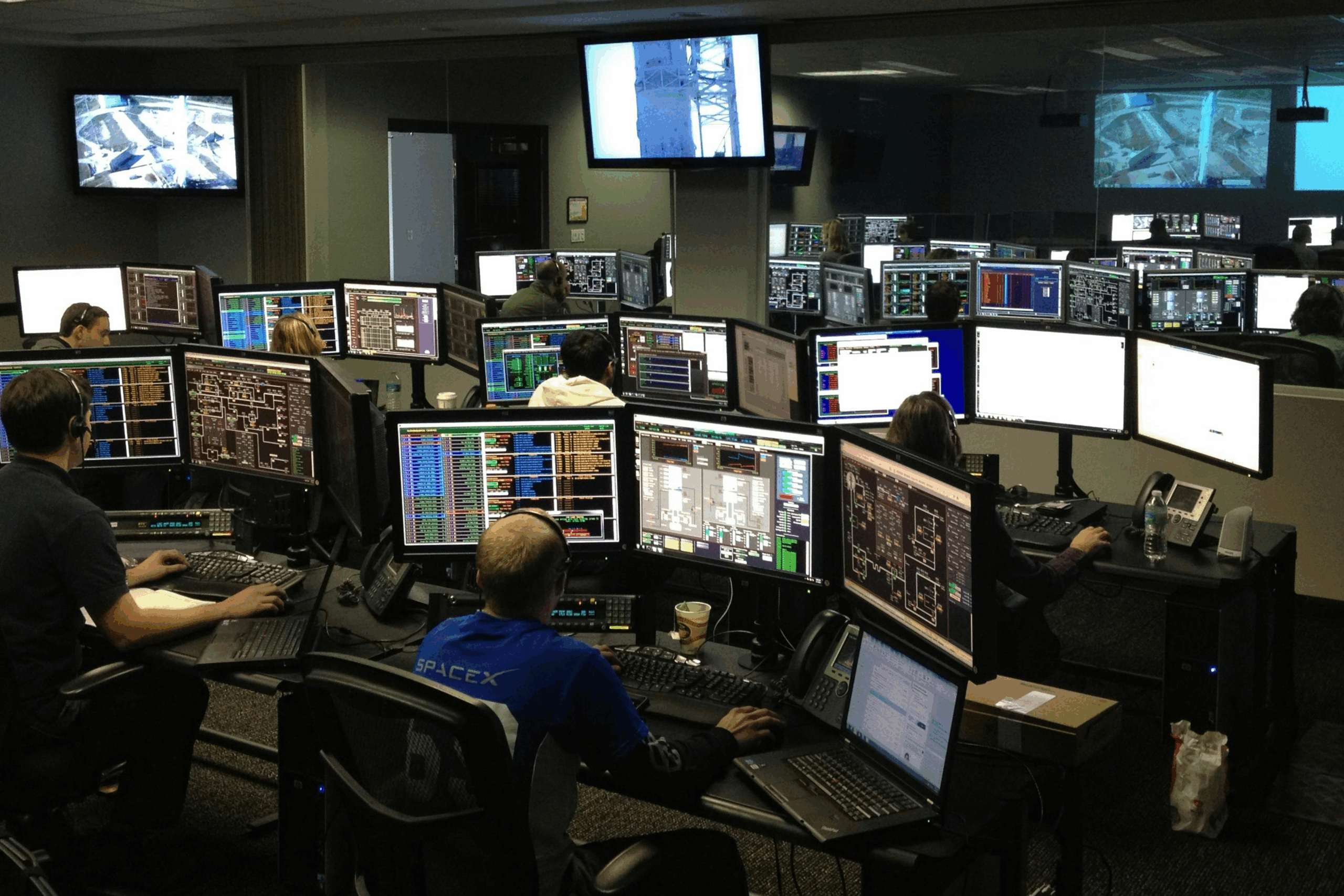

These sectors rely on strong, clean and reliable wiring systems that support long-term operation in demanding environments.

Marine &

Offshore

Defence &

Military

Automotive &

Electric Vehicles

Medical &

Healthcare Equipment

Telecommunications &

Surveillance

Industrial Automation &

Robotics

Rail, Transport &

Infrastructure

Audio & Music Industry

Request a Cable Assembly or Box Build Quote

To provide an accurate and reliable quotation for cable assemblies or full box-build projects, please share the key details of your requirements. This helps us assess complexity, materials, labour and any specialist processes needed, ensuring we respond quickly with clear pricing, expert guidance and realistic lead-time expectations.