Professional BGA Re-work Services in Portsmouth

Precision BGA removal, replacement and repair handled with care, accuracy and controlled thermal expertise.

Phase One Electronics provides specialist Ball Grid Array (BGA) re-work for UK businesses that require safe, reliable and technically controlled removal, replacement and repair. With over 35 years of experience, we re-work BGAs without damaging the PCB, surrounding components or internal board layers offering a cost-effective alternative to scrapping valuable assemblies.

Why Choose Phase One Electronics for BGA Re-work?

BGA re-work is one of the most delicate procedures in electronics manufacturing. It requires exceptional thermal control, precise alignment and highly trained technicians. Our facility, tools and expertise are specifically developed to safely handle complex BGA repairs, removals and replacements.

Skilled Technicians with Decades of Experience

Clean, Repeatable and Carefully Monitored Processes

Controlled Thermal Profiles and Professional Re-work Equipment

Ideal for Prototypes, Repairs and Production-Level Re-work

Guaranteed Protection of Surrounding Components

Full UK-Based Re-work Facility

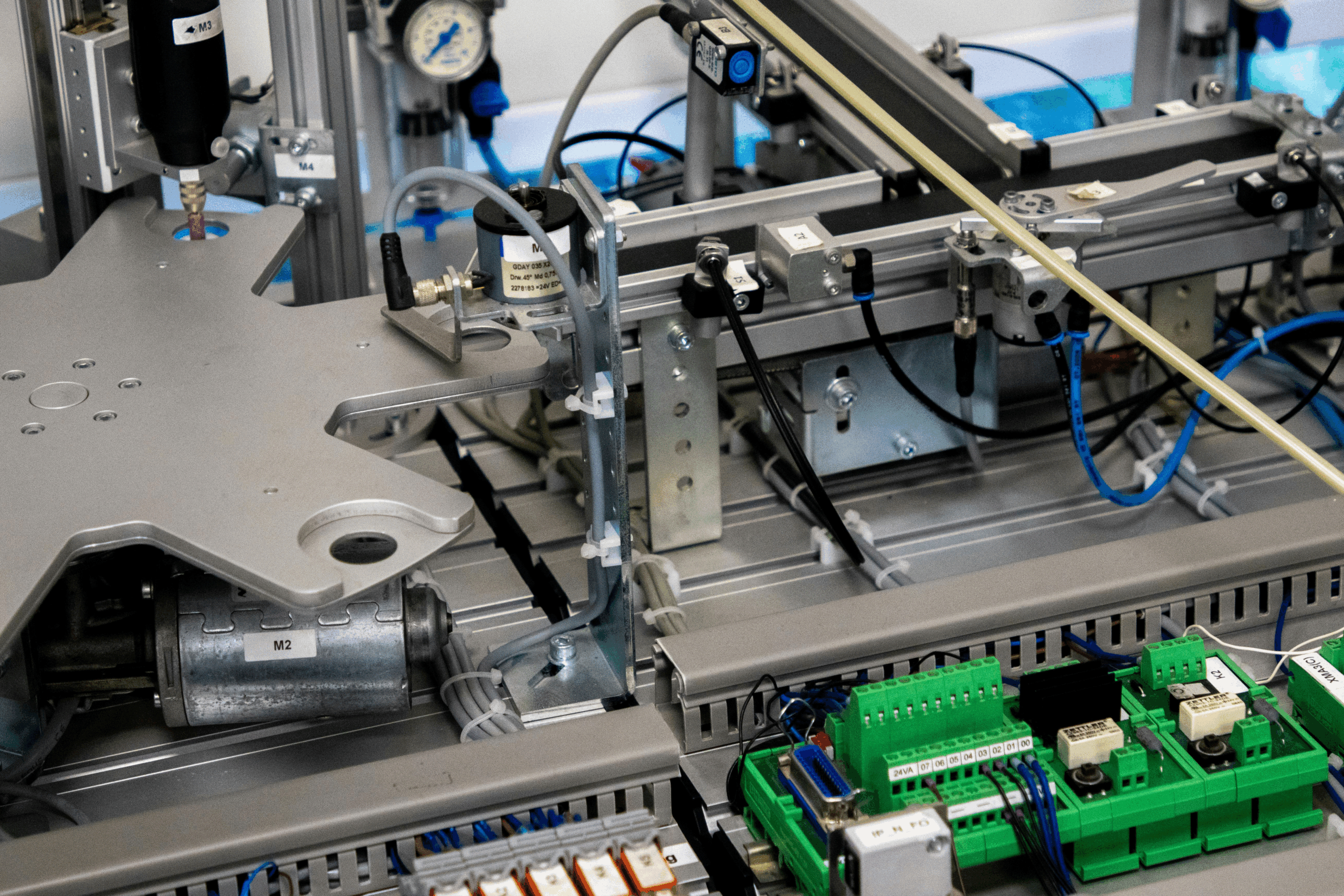

Our Complete BGA Re-work Process

Our BGA re-work procedure has been refined over decades to ensure safe, controlled and repeatable results. Every step is performed by trained technicians using dedicated re-work equipment designed to protect your PCB, maintain pad integrity and deliver reliable solder joints.

Initial Assessment and Feasibility Review

Controlled Heating and BGA Removal

Pad Cleaning and Preparation

Component Alignment and Placement

Reflow Soldering with Controlled Thermal Profiles

Post-Reflow Inspection and Verification

Electrical Testing and Functional Checks

Industries That Rely on Our BGA Re-work Expertise

BGA technology is widely used across advanced and high-reliability applications. Because BGA failure can result in costly downtime or unsafe operation, our re-work service is trusted by industries that require consistent performance, stable operation and precision repair capability.

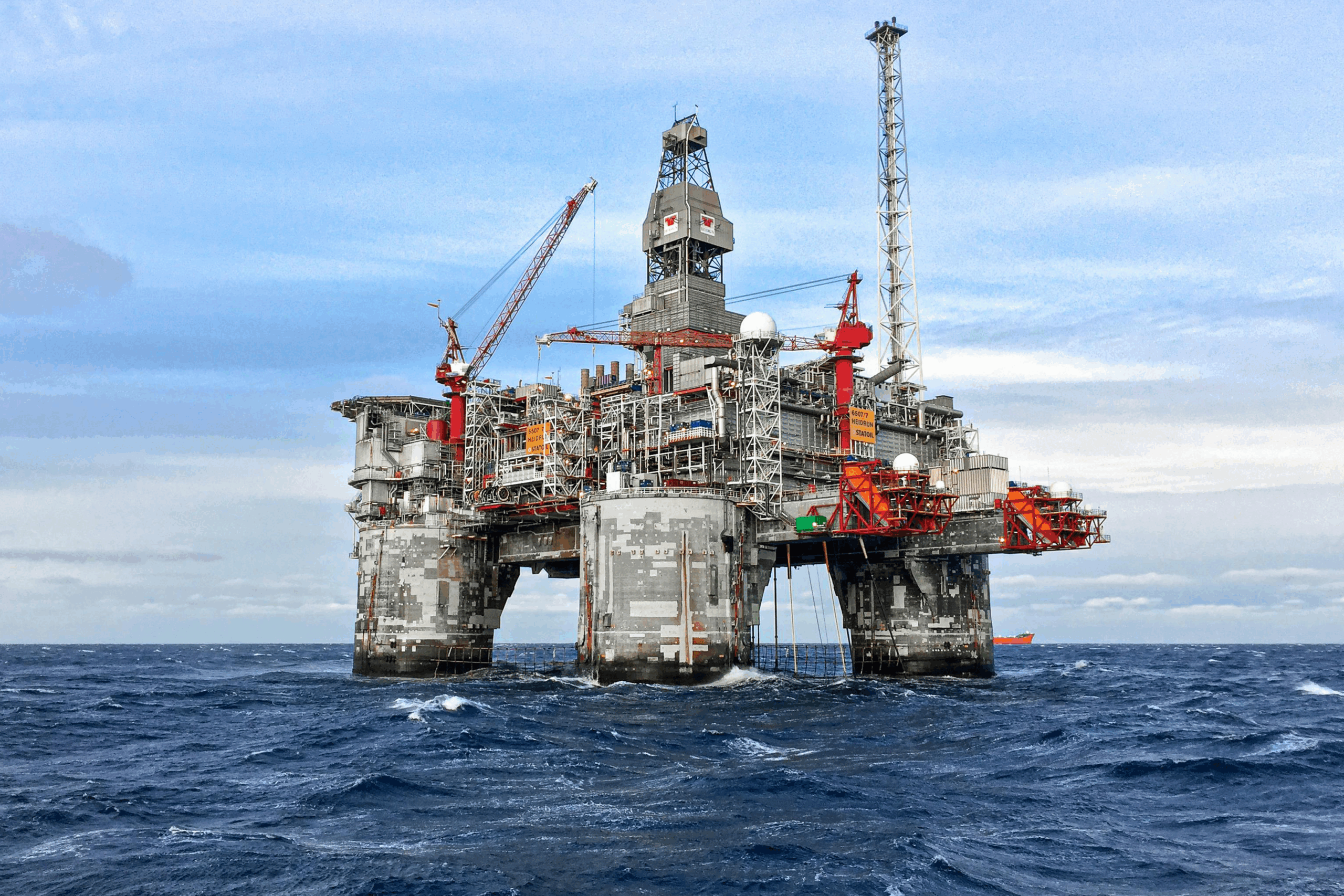

Marine &

Offshore

Defence &

Military

Automotive &

Electric Vehicles

Medical &

Healthcare Equipment

Telecommunications &

Surveillance

Industrial Automation &

Robotics

Rail, Transport &

Infrastructure

Audio & Music Industry

Supporting All Types of BGA Packages

Our re-work facility handles a wide range of BGA formats, from compact micro-devices to large, high-pin-count processors. Whether your assembly requires simple removal or complete replacement, our technicians work with the precision and thermal control these devices demand.

PBGA (Plastic Ball Grid Array)

Micro-BGA / Fine-Pitch BGA

FPGA and Processor-Grade BGAs

CSP (Chip-Scale Packages)

CBGA (Ceramic Ball Grid Array)

eMMC, Flash Memory & Storage BGAs

LGA (Land Grid Array)

Request a BGA Re-work Quote

To provide an accurate quotation for BGA removal, replacement or re-work, please send us the details of your project. We respond quickly with clear pricing, expert guidance and reliable turnaround expectations.