Inspection & Test Services for PCB Assembly

Ensuring Reliability, Consistency and Long-Term Performance

At Phase One Electronics, we provide detailed inspection and testing when requested by the customer or required by the project specification. With over 35 years of experience, our trained technicians carry out visual inspection, continuity testing, functional testing and customer-defined verification processes — all completed at our Portsmouth, UK facility.

Why Phase One Electronics Is Trusted for PCB Inspection & Test

Our inspection and testing service is built around customer requirements, accuracy and more than 35 years of hands-on manufacturing experience. Every PCB is checked by trained technicians who understand how faults occur — and how to prevent them.

Over 35 Years of Quality Control Experience

Skilled Technicians Trained to Industry Standards

Proven Processes That Identify Defects Early

Suitable for All PCB Types

100% UK-Based Inspection Facility

Flexible Testing Options

Ideal for High-Reliability Applications

Our Full Inspection

& Test Workflow

Our inspection and test workflow has been refined over decades to ensure accuracy and consistency. Testing is performed only where required by the customer or the assembly specification.

1. Incoming Inspection & Documentation Review

2. Visual Inspection During Assembly

3. Final Visual Inspection (Post-Assembly)

4. Optical & Magnified Inspection

5. Continuity Testing (When Requested)

Advanced Testing, Validation

& Final Quality Assurance

Additional testing options are available when defined by the customer’s requirements.

6. Functional Testing (Customer-Defined)

7. Programming & Firmware Loading (Optional)

8. Mechanical Testing & Fit Checking (Optional)

9. Burn-In Testing (Optional)

10. Documentation, Reporting & Full Traceability

Industries That Rely on Our Inspection & Test Service

We work with organisations whose products must perform reliably under demanding conditions.

Our inspection and testing processes are trusted by industries where long-term stability, safety and consistency are essential.

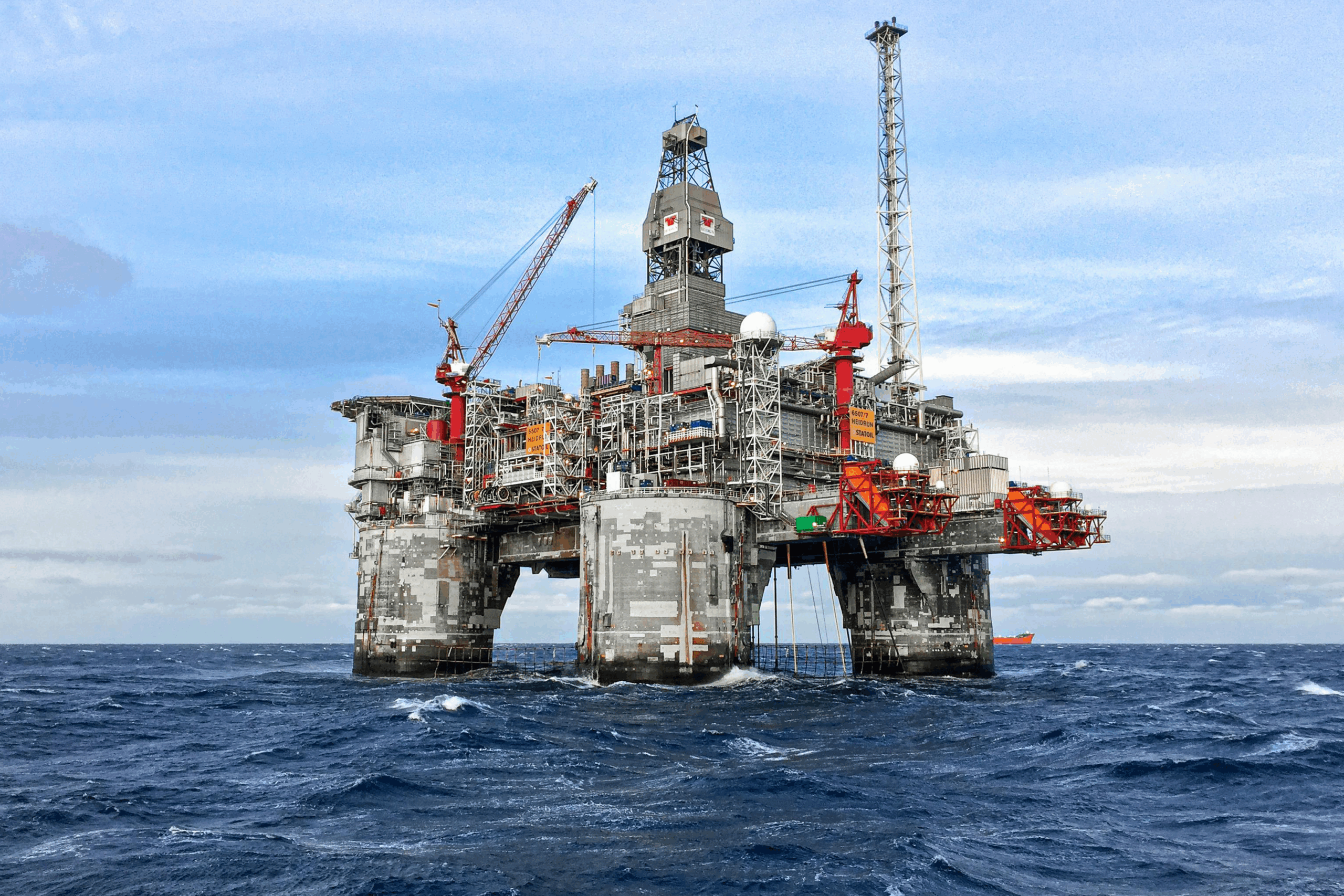

Marine &

Offshore

Defence &

Military

Automotive &

Electric Vehicles

Medical &

Healthcare Equipment

Telecommunications &

Surveillance

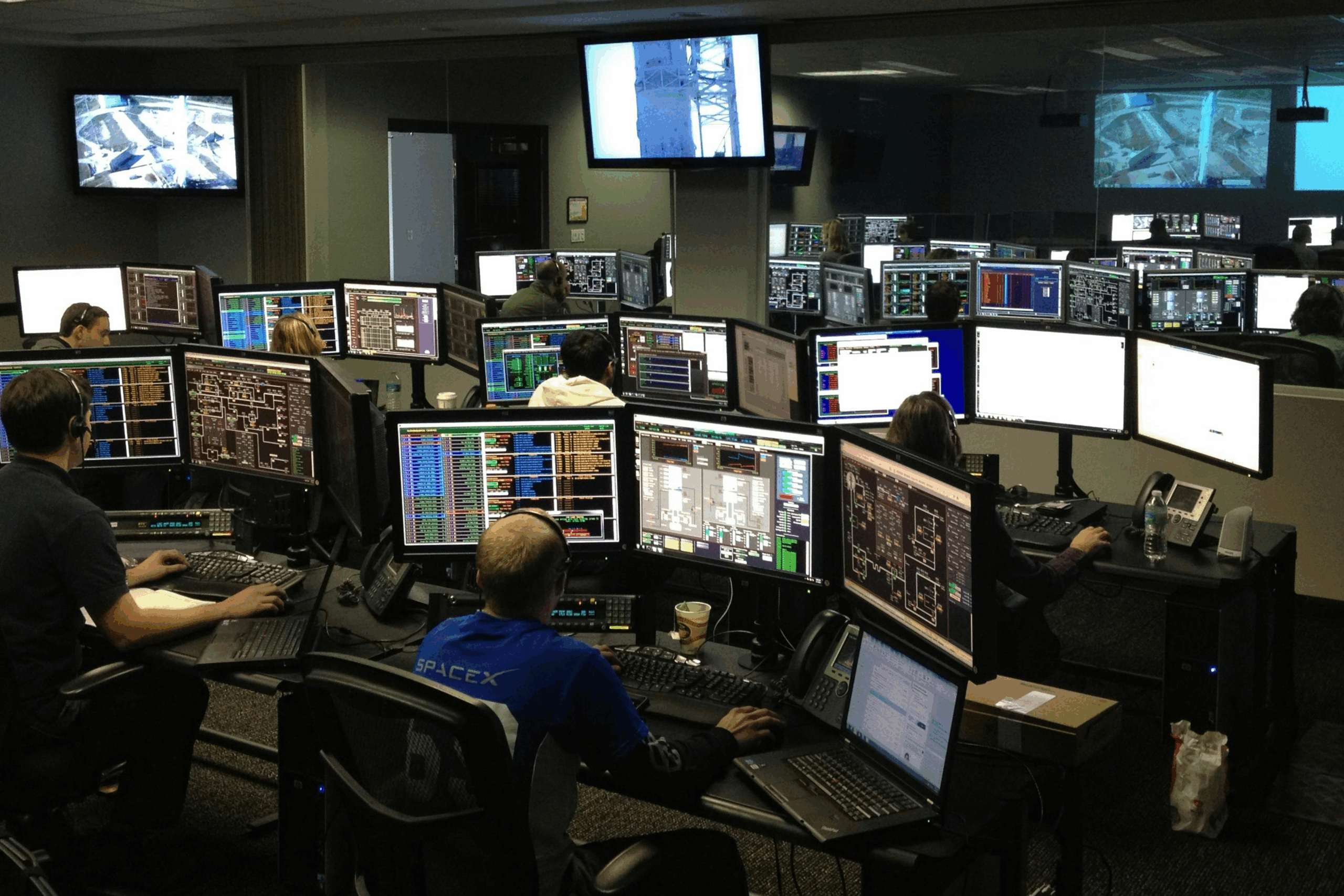

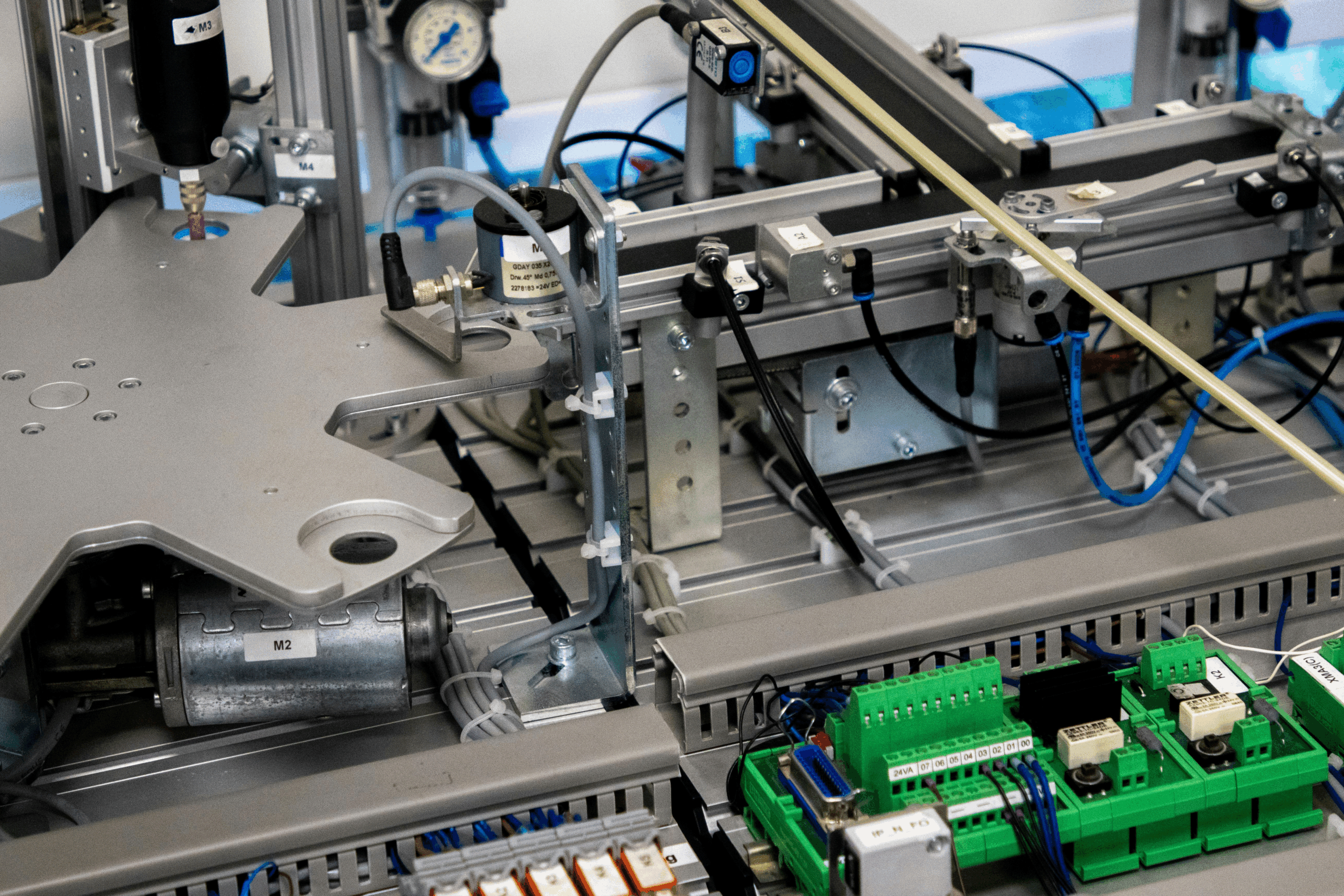

Industrial Automation &

Robotics

Rail, Transport &

Infrastructure

Audio & Music Industry

Flexible Testing Options: From Prototype to Production

Our inspection and testing service is designed to support every phase of your product’s lifecycle. Whether you are developing early prototypes or managing long-term production, we offer a range of testing levels to ensure your PCB assemblies are validated correctly.