SMT vs Through-Hole Assembly: Which Is Right for Your Project?

Surface Mount Technology (SMT) and Through-Hole Technology (THT) form the backbone of modern PCB assembly. While SMT dominates today’s electronics manufacturing thanks to its speed, precision and ability to support extremely compact designs, through-hole assembly still plays a critical role in specific high-reliability and high-strength applications.

For engineers, designers and purchasing teams, selecting the right approach early in a project can reduce costs, improve reliability and prevent delays during manufacturing. However, knowing which technique to choose—SMT, THT, or a combined hybrid approach—depends on the device’s performance requirements, environment, expected lifespan and physical constraints.

This guide breaks down everything you need to know. We’ll cover how each assembly method works, where each one excels, the limitations to be aware of, and how UK manufacturers are combining both processes to achieve the best results across industries such as automotive, aerospace, medical, industrial control and consumer electronics.

By the end, you’ll have a clear understanding of which assembly route aligns best with your next project, helping you avoid unnecessary redesigns, cost overruns or performance issues.

PCB assembly has evolved dramatically over the last three decades. SMT machines now place tiny 01005 components with exceptional speed and accuracy, enabling high-density circuits for smartphones, EV battery systems, industrial sensors and medical wearables. At the same time, through-hole soldering—both wave and selective—remains widely used for components requiring superior mechanical stability or long-term reliability.

Understanding the operational and performance differences between these technologies allows organisations to optimise cost, manufacturability and long-term durability. In many cases, a mixed-technology approach is the ideal solution.

What Is SMT Assembly?

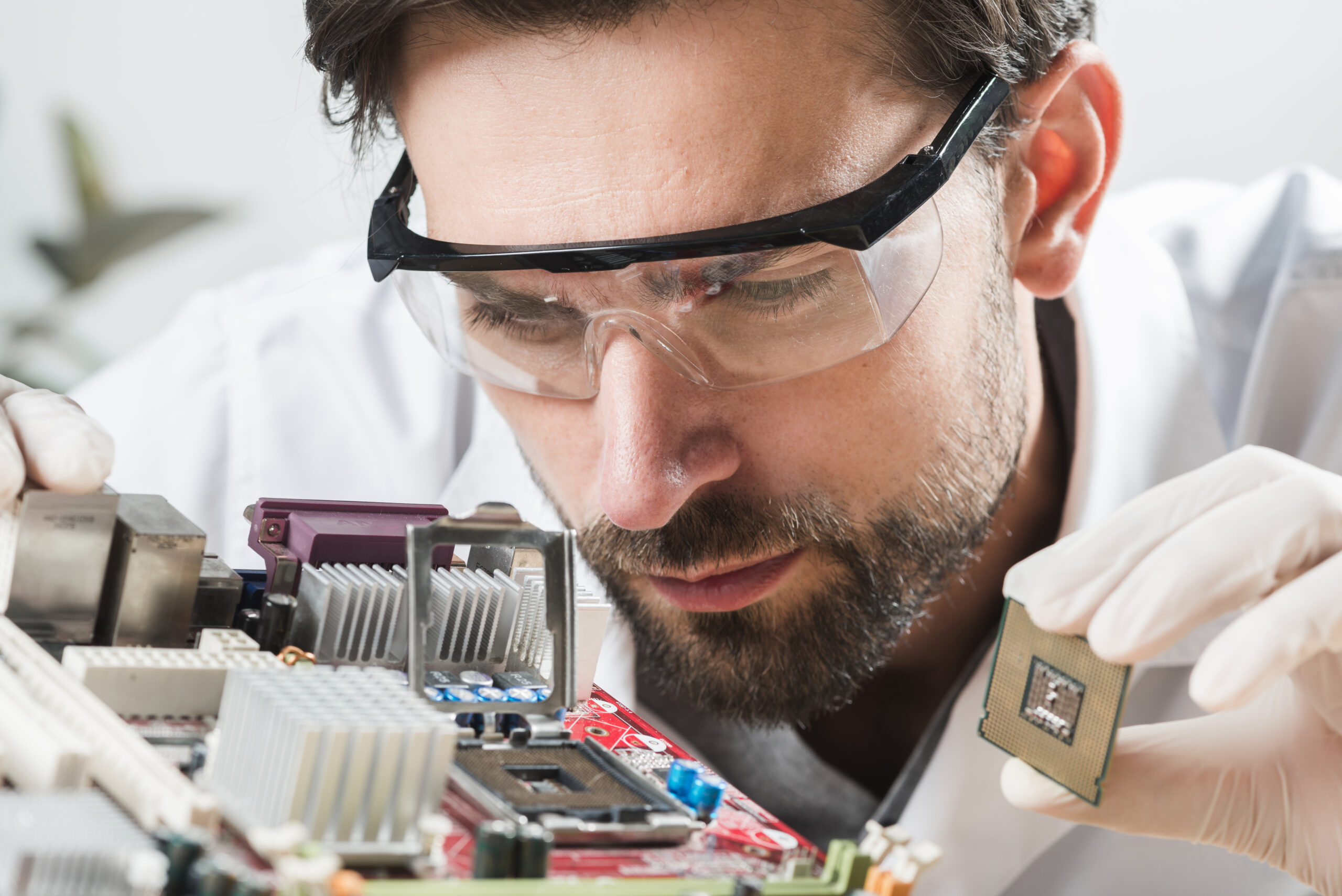

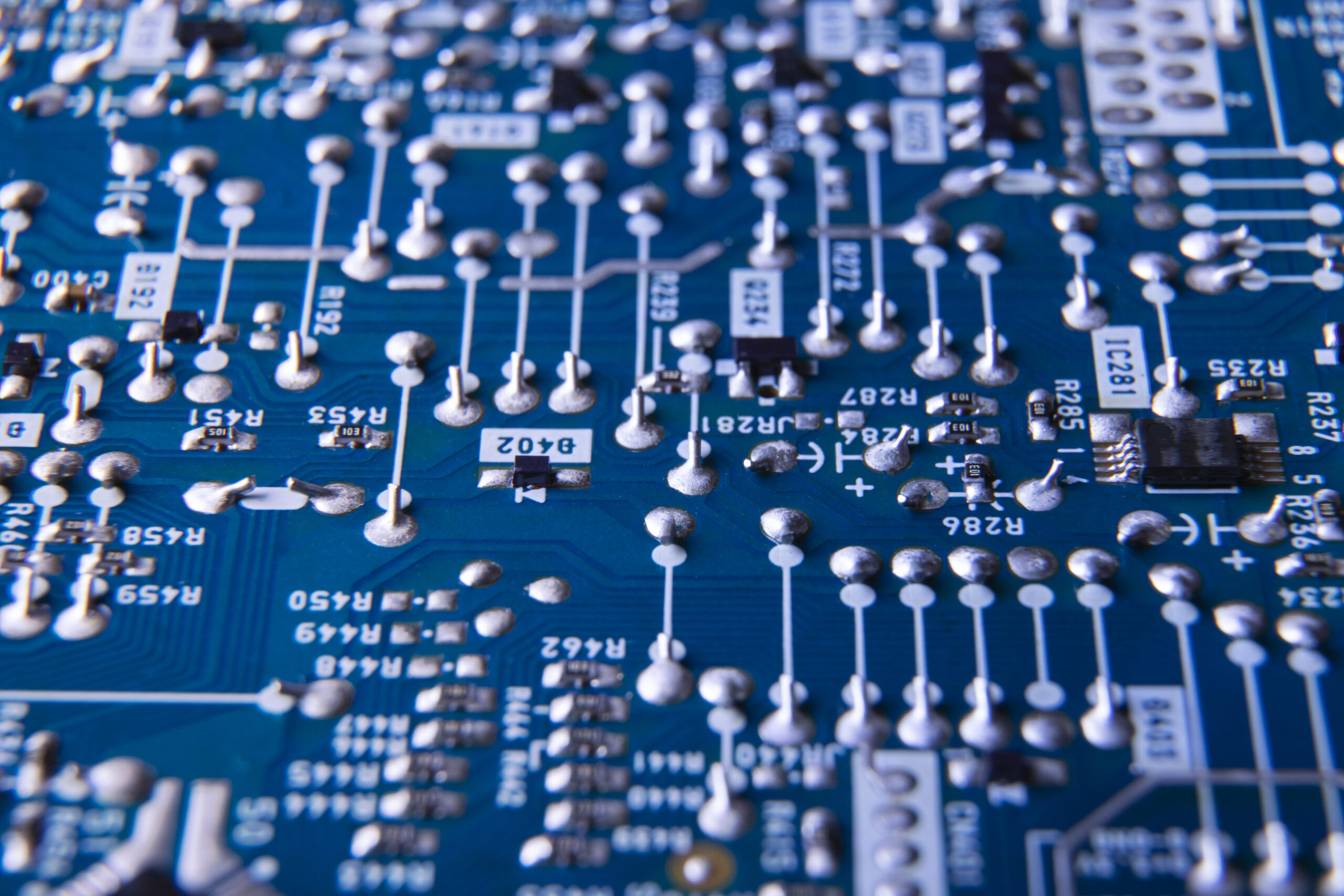

Surface Mount Technology (SMT) refers to the process of mounting components directly onto the surface of a PCB. These components, known as surface-mount devices (SMDs), do not require leads to pass through the PCB. Instead, they are soldered to pads using reflow soldering.

SMT has become the industry standard due to its scalability, precision and ability to dramatically reduce PCB size. A modern SMT line consists of solder paste printing, automated placement machines (pick-and-place), reflow ovens and advanced inspection systems such as AOI and X-ray.

Key benefits of SMT include:

- Support for extremely compact product designs.

- High-speed automated assembly for cost-effective production.

- Improved electrical performance due to shorter signal paths.

- Greater thermal efficiency for high-power applications.

- Compatibility with high-density and multi-layer PCBs.

SMT is ideal for most modern products, from IoT sensors to industrial power modules. However, it is not always suitable when mechanical strength or environmental robustness is required.

SMT requires highly controlled processes. Solder paste volume, placement accuracy and thermal profiling all have a significant impact on final quality. For fine-pitch components, even minor deviations can lead to issues such as bridging, tombstoning or insufficient solder joints.

Despite this, SMT delivers exceptional repeatability when production is properly controlled. It is a cornerstone of high-volume electronics and essential for modern compact product design.

Through-Hole Assembly and Its Benefits

Through-Hole Technology (THT) involves inserting component leads through pre-drilled holes in a PCB. These leads are soldered either manually or using wave or selective soldering systems. Although considered the older of the two processes, THT remains crucial for many mission-critical electronics.

Key advantages of THT include:

- Exceptional mechanical strength, ideal for connectors and large components.

- Superior reliability in high-vibration or high-shock environments.

- Improved durability for high-power or high-temperature components.

- Preferred for aerospace, automotive, defence and industrial control applications.

Examples of components commonly assembled using THT include transformers, relays, electrolytic capacitors, high-current terminals and large connectors. These components require strong solder joints that can withstand repeated mechanical stress.

THT is often essential when safety and long-term reliability must be guaranteed. In sectors such as EV battery management, aviation electronics and heavy-industrial machinery, through-hole assembly provides the mechanical resilience required to avoid failures in harsh conditions.

While THT is more labour-intensive than SMT, modern selective soldering machines provide consistent quality while reducing operator involvement. This enables UK manufacturers to deliver high-quality mixed-technology assemblies at competitive prices.

Choosing Between SMT and Through-Hole: Key Considerations

Choosing the right assembly method depends on several important factors. In many projects, a hybrid SMT/THT approach is preferred to achieve the ideal balance of performance, durability and cost.

When to use SMT:

- Compact product designs with limited PCB space.

- High-volume production requiring cost efficiency.

- High-speed, high-frequency or precision electronics.

- Products where weight and size must be minimised.

When to use THT:

- Components subjected to vibration, shock or mechanical stress.

- High-current or high-power circuits requiring robust joints.

- Large components such as transformers or power connectors.

- Safety-critical applications requiring maximum reliability.

When to use a mixed approach:

- Products that combine fine-pitch logic circuits with heavy mechanical components.

- Industrial and automotive electronics.

- Power systems requiring both precision and durability.

- Consumer devices needing small form factors and robust connectors.

UK manufacturers frequently build mixed-technology PCBs for industrial, automotive and consumer applications. Combining SMT and THT ensures the board meets both performance and durability requirements without unnecessary cost escalation.

Working with a capable assembly partner early in the design phase can help ensure your PCB layout supports efficient manufacturing, reducing lead times and eliminating the risk of rework.

How UK PCB Manufacturers Support Both Processes

UK electronics manufacturers increasingly offer advanced mixed-technology assembly lines to support a wide range of industries. These facilities combine high-speed SMT placement lines with selective soldering and manual THT skills, enabling them to handle prototypes, small batch production and high-volume builds.

A strong partner should offer:

- State-of-the-art SMT equipment and AOI inspection.

- Experienced THT operators and selective soldering capability.

- Design for Manufacture (DFM) guidance to help optimise layouts.

- Traceability for components and processes.

- Functional testing to validate performance.

By working collaboratively, UK manufacturers help ensure your product meets both performance and environmental requirements while maintaining competitive lead times and costs.